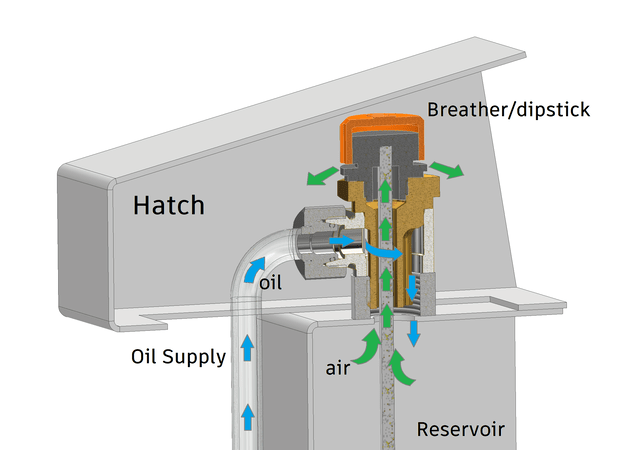

Embarking on any project inevitably brings forth a myriad of challenges, often manifesting in the guise of constraints. The more rules we have, the harder the problem becomes. In a recent endeavor, our client presented us with the task of enhancing an existing product, specifically an oil reservoir in need of additional functionality.

The primary hurdle was the scarcity of available ports on the tank, leaving us with the sole option of utilizing the pre-existing oil supply line. Complicating matters further, the space above this supply line port was limited, and the oil supply line itself could be rotated during installation. These constraints underscored the complexity of the project.

A pivotal issue we encountered was the imperative need to separate the air flow from the oil flow. A failure in achieving this separation would result in the undesirable scenario of oil coursing through the air channel, eventually escaping through the breather. Adding to the challenge was a height restriction imposed by a service hatch positioned above the reservoir.

Navigating these intricate challenges, our team successfully devised a two-part solution that effectively segregated the air and oil flows. Importantly, this solution seamlessly adhered to the spatial constraints without compromising any aspect of the functionality. The culmination of our efforts yielded a revamped setup equipped with a breather and dipstick, ensuring the enhanced performance of the oil reservoir. In overcoming these obstacles, we not only addressed the client’s immediate needs but also showcased our ability to innovate within the confines of stringent project limitations.